EASIKIT ACCESSORIES

Choose the length, motor, and belting type to suit your operation. Don’t forget to add on standard accessories to maximize the performance of your EASIKIT Conveyor in your unique environment.

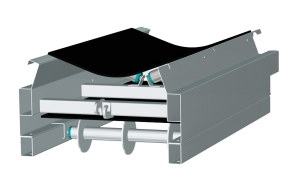

DISC RETURN ROLLERS

Fitted with metal discs to help prevent material buildup on the roller itself. Recommended for use with sticky or difficult materials.

Only suitable for use with plain or cleated belt. Not required for chevron belting.

*Note: Disc return rollers supplied as standard with EK450

AUTO GREASE UNITS

This is a self-contained unit to automatically lubricate the bearing over a period of 1 to 12 months. Once fitted and activated, it will work without attention until it’s allotted lifespan is over.

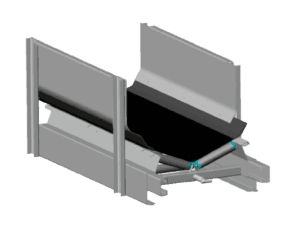

BELT SCRAPERS

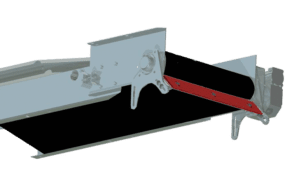

PRIMARY BELT SCRAPER

A cost-effective way to prevent material carry-back on the return belt when conveying viscous material. Suitable for a plain belt and clipped or vulcanized joints, the primary scraper has a manually adjustable polyurethane blade and is mounted on the drive drum bearing for easy fitting.

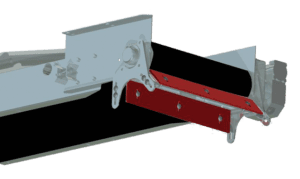

SECONDARY BELT SCRAPER

Assist the primary scraper in helping to prevent material carry-back on the return belt. Suitable for a plain belt and clipped or vulcanized joints, the secondary scraper is mounted behind the primary scraper and shares the same bracket as the Primary Scraper mounted onto the drive drum bearing. The scraper has a manually adjustable polyurethane blade which provides a good back up when fitted with the primary scraper, especially when handling sticky material, i.e. sewage cake.

SELF-ADJUSTING BELT SCRAPER

This is the perfect solution for keeping your belt clean when access to the drive drum is difficult and you want peace of mind that your belt will be kept clean without the need to manually adjust the scraper blade. Ideal for conveyors in locations where low maintenance is required.

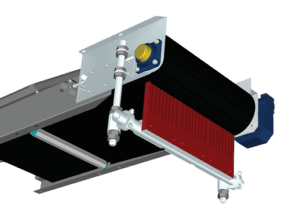

FINGER BELT SCRAPER

These are the ultimate option for keeping your belt clean. The heavy duty finger scrapers are suitable for cleaning chevron belt or plain belt if required. The scrapers come supplied complete with a heavy-duty mounting frame.

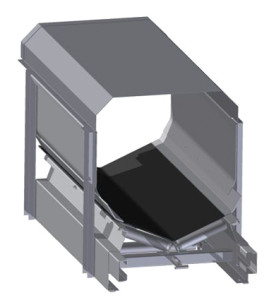

COVERS & SIDE GUIDES

SIDE GUIDES

Side guides are used to control spillage of loose, bulky material. Standard heights of 6″ (150mm) and 12″ (300mm) are available with continuous rubber side skirts.

*Note: Pricing and availability for EK1500 side guides available on request and dependent on application.

SIDE GUIDE TOP COVERS

These top covers are designed to fit on top of our standard side guides. Provides the solution when required to have both a continuous rubber skirt on to the belt and an easily removable cover for maintenance.

MESH BOTTOM COVERS

Provided to enclose the running length of the conveyor with mesh panels, supplied in 3.3′ (1m EK450) or 4′ (1.2m) long sections and secured with nut and bolt fixings, they are supplied as an extra when needed for health and safety. They are a recommended requirement when using cleated or chevron belt. *Solid Bottom Covers are a special order item, available on request.

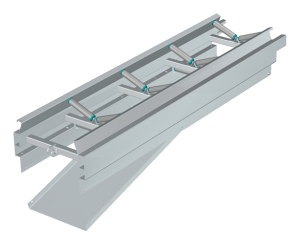

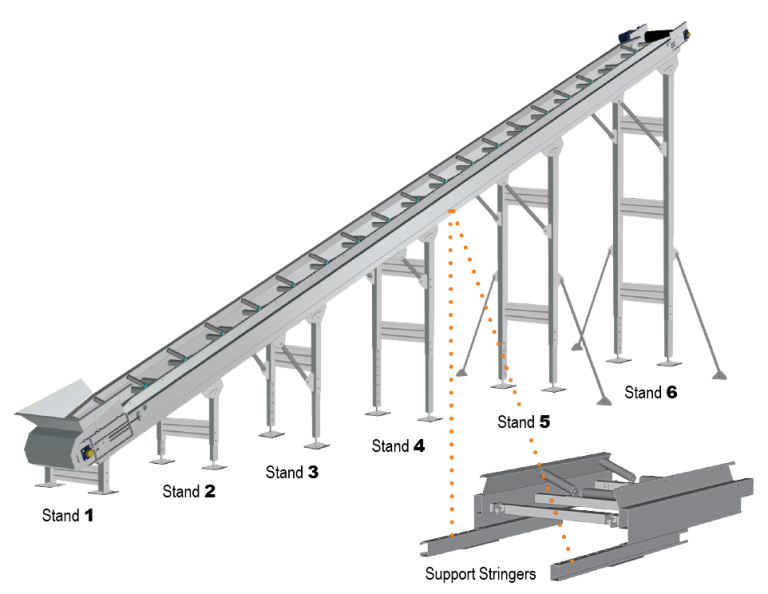

SUPPORT STANDS & STRINGERS

ADJUSTABLE SUPPORT STANDS

Our modular support system for EASIKIT Conveyors is a cost-effective, combined design. The stands utilize a modular design with cross bracing for heights up to 20 ft. or higher, depending on site conditions.

*Note: Pricing and availability for EK1500 support stands available on request.

SUPPORT STRINGERS

Fitted to the underside of the conveyor frame in modular 4′ (1.2m) and 8′ (2.4m) lengths. Provides adequate support for spans of up to 20 ft. centers (depending on loading). Constructed from galvanized C-section, thus increasing conveyor frame height by 3″ (75mm). This can also be used as a cable tray.

*Note: For more information on assembly of Adjustable Support Stands and Support Stringers go to EASIKIT Resources.