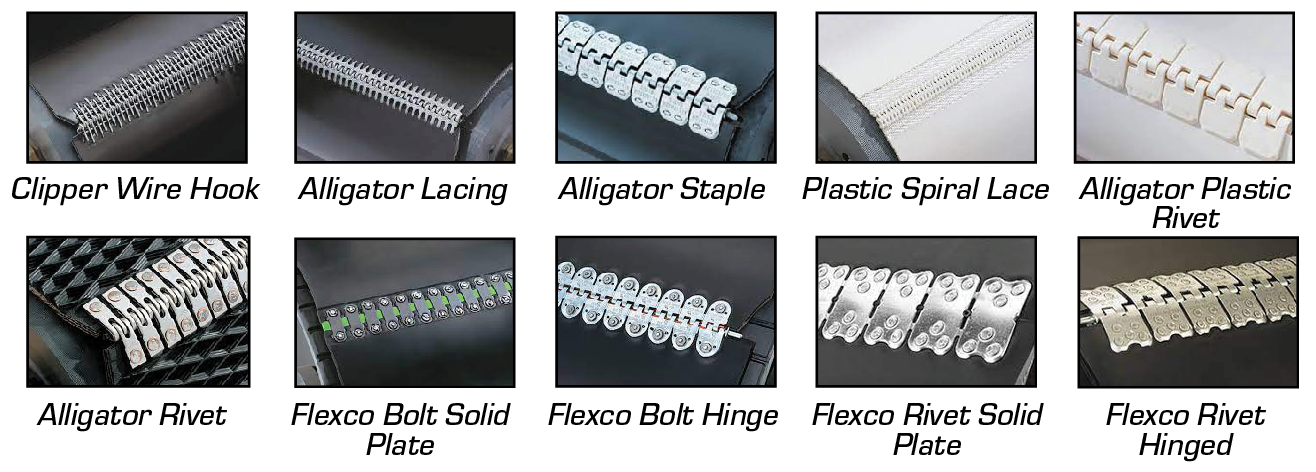

LACING & SPLICING

Selecting the correct lacing option for your belt is critical. We offer a variety of lacing styles and materials to meet the needs of every application.

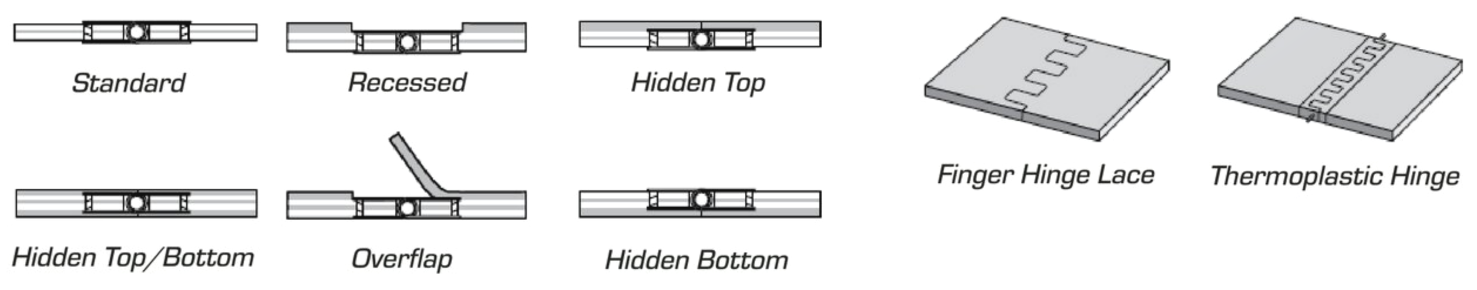

CUSTOM SPLICING OPTIONS

RECESSED LACE

Mechanical splice area is recessed below the belt surface.

OVERFLAP

Mechanical lacing is installed below the belt surface and the top cover is seperated from the belt carcass creating a flap over. The cover flap can be glued down after installation.

HIDDEN LACE

Mechanical fasteners are installed below the belt cover to prevent the lace from contacting the product.

FINGER HINGE LACE

Finger hinge lace is equipped with flexible, hinged plastic lacing, creating as easy, quick repair alternative to endless belts. FHL requires the belt be made of PVC orpolyurethane, have a thickness of .08″ to .263″, have a minimum belt length of 55″, and a maximum belt width of 40″.

THERMOPLASTIC HINGE

Thermoplastic hinge lace is amde with the same homogenous material as your belt. This lace is welded to the belt and connect with a metal of nylon pin. Nylon pins should be used when metal detectors are required. (This option is availble for Volta products only.)

ENDLESS NON-MECHANICAL SPLICING SOLUTIONS

Endless splicing methods eliminate the need for hardware fasteners. This fabrication technique is excellent for food processing applications where products need to be handled with greater care.

STEP SPLICE BELT

For belts with multiple plies. Plies are separated and “stepped” to interlock with one another at the splice point.

SKIVED SPLICE

A precision grinding technique is used to achieve uniform thickness at the splice point for a variety of applications.

FINGER SPLICE

For thermoplastic, urethane, and PVC belts. A very durable splice that maintains a smooth belt surface throughout the splice area. Multiple finger patterns are available to meet a variety of applications and system pulley sizes.

ENDLESS-PREPARED

We square and prepare the belt’s ends for hot or cold cement bonding at the customers site. (Cement bonding kits with instructions are available.)

DOUBLE FINGER SPLICE

Unlike a standard finger splice, fingers are cut from multiple plies, staggered, then fused together by heat and pressure to create a stronger, more flexible splice.

STITCHED REINFORCEMENT

Certain applications put unusual wear on splices and edges. These areas can be strengthened with stitching.

LONGITUDINAL SPLICING

Very wide belts are created by longitudinally splicing two or more belts of narrower dimension. Plies are expertly stepped and bonded to create a uniformly smooth belt as wide as the application requires. Ultra-wide belts can be made endless prior to shipping or have ends prepared for field splicing. V-guides and other profiles can also be added.

Request a Quote Today!

Please complete the form below