MODULAR BELT CONVEYOR SOLUTIONS FOR

SEWAGE & WATER TREATMENT PLANTS

Sewage and water treatment plants dump the screw conveyor for trough belt conveyors!

Why is the screw conveyor “old news” for sewage and water treatment plants? INTERQUIP CONVEYORS is fast-becoming America’s partner for material management. By developing conveying products with industry professionals for 32 years, INTERQUIP CONVEYORS are replacing the traditional equipment found throughout the water treatment industry to handle sewage sludge.

Founded over 3 decades ago, INTERQUIP CONVEYORS can still be found in numerous sewage and water treatment plants. The INTERQUIP alternative provides plants with reliable and efficient service many years after their installation.

Many water authorities have proven the beenfit of resorting to INTERQUIP CONVEYORS’ Model EK600 trough belt conveyors over the traditional screw conveyor.

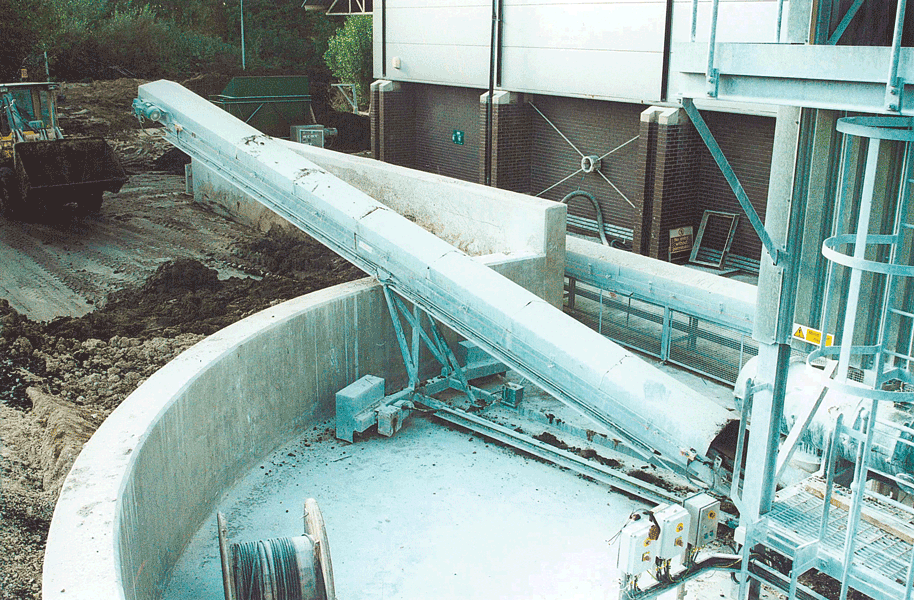

One such authority who intended to operate a screw conveyor at their sewage treatment plant to take de-watered sludge from the plant to a small far trailer rented an EK 600 during the time they were awaiting the delivery of a new screw conveyor. Unfortunately, when they had received and commissioned the screw conveyor, they found it was changing the consistency of the sludge being handled and as this was clearly not acceptable for the application, the new screw conveyor was quickly decommissioned!

They then chose another EK600 mobile conveyor as a temporary solution and found it so successful in handling the sludge without degradation, that they placed an order for two conveyors for permanent installation.

Now, one 10′ conveyor receives the material from the belt press and feeds a 30′ EK600 Radial Conveyor, which in turn elevates the material to two farm trailers. This conveyor is mounted on a motorized slewing carriage. This arrangement enables the conveyor to feed the full length of two trailers without the trailers being moved and using the maximum amount of space in both trailers.

CUSTOM CONFIGURATIONS AVAILABLE FROM STOCK!

INTERQUIP CONVEYORS come fully galvanized for weather resistance and can be fitted with covers over the belt to protect the sludge from dilution by rain. Over many years of experience gained in handling sludge, INTERQUIP CONVEYORS have included a whole host of other features, all of which contribute to ensuring that the sludge is removed cleanly, effectively and quickly, with the minimum amount of maintenance required on the equipment.

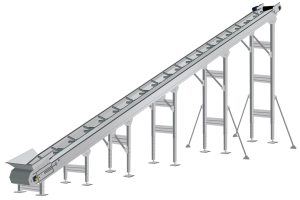

INTERQUIP CONVEYORS are available in widths from 12″ to 60″ wide. The EK600 has proven to be the most popular model for handling sewage sludge and is capable of handling in excess of 60 tons per hour! Almost any length can be constructed by joining the modular sections together. The beauty of the system over other custom systems available is that once on site, sections and belting can be added or subtracted as needed should requirements change.

The heavy-duty support system is a cost-effective, combined design. The predrilled beams used for the stands are also used for the support stringers to provide additional support when longer spans are needed. The modular design with cross-bracing can support heights 20 feet or higher, depending on site conditions.

INTERQUIP CONVEYORS can be supplied either in static, fixed form or as a Mobile or Radial conveyor. These conveyors come with an undercarriage fitted with a hydraulic ram which enables the conveyor to have a variable discharge height. The Mobile conveyor has pneumatic wheels and an optional tow hitch for maneuverability on site. The fixed Radial conveyor comes supplied with an electrically powered motor on the undercarriage and is capable of rating through a full 360-degree arc, essential when stockpiling.

Part of the unique design is the attention to safety. On all the conveyors the belt travels over the folded edge of the mainframe. This reduces the likelihood of material dropping down on to the returning belt. Idlers are therefore concealed during normal use. This is an ideal safety factor, especially where conveyors are used in close proximity to personnel.

All products receive the reassurance of a 12-month warranty and the added advantage of ex-stock back up for spares which is invaluable to assist with ongoing maintenance.